How they're made

IBSA FilmTec® technology is based on Maltodextrin as the main component, which has the advantages of being a common food ingredient and having a good palatability. These features allow the ODF to dissolve quickly without leaving any aftertaste.

The orodispersible film is manufactured according to the steps below

Step 1 - Mixture preparation

All ingredients are dissolved in a water-based mixture which is prepared under the control of the temperature and the stirring speed of the mixer.

Step 2 - Coating and drying

The mixture is spread on the intermediate liner and dried in a drying tunnel, controlling temperature, air circulation, and coating speed.

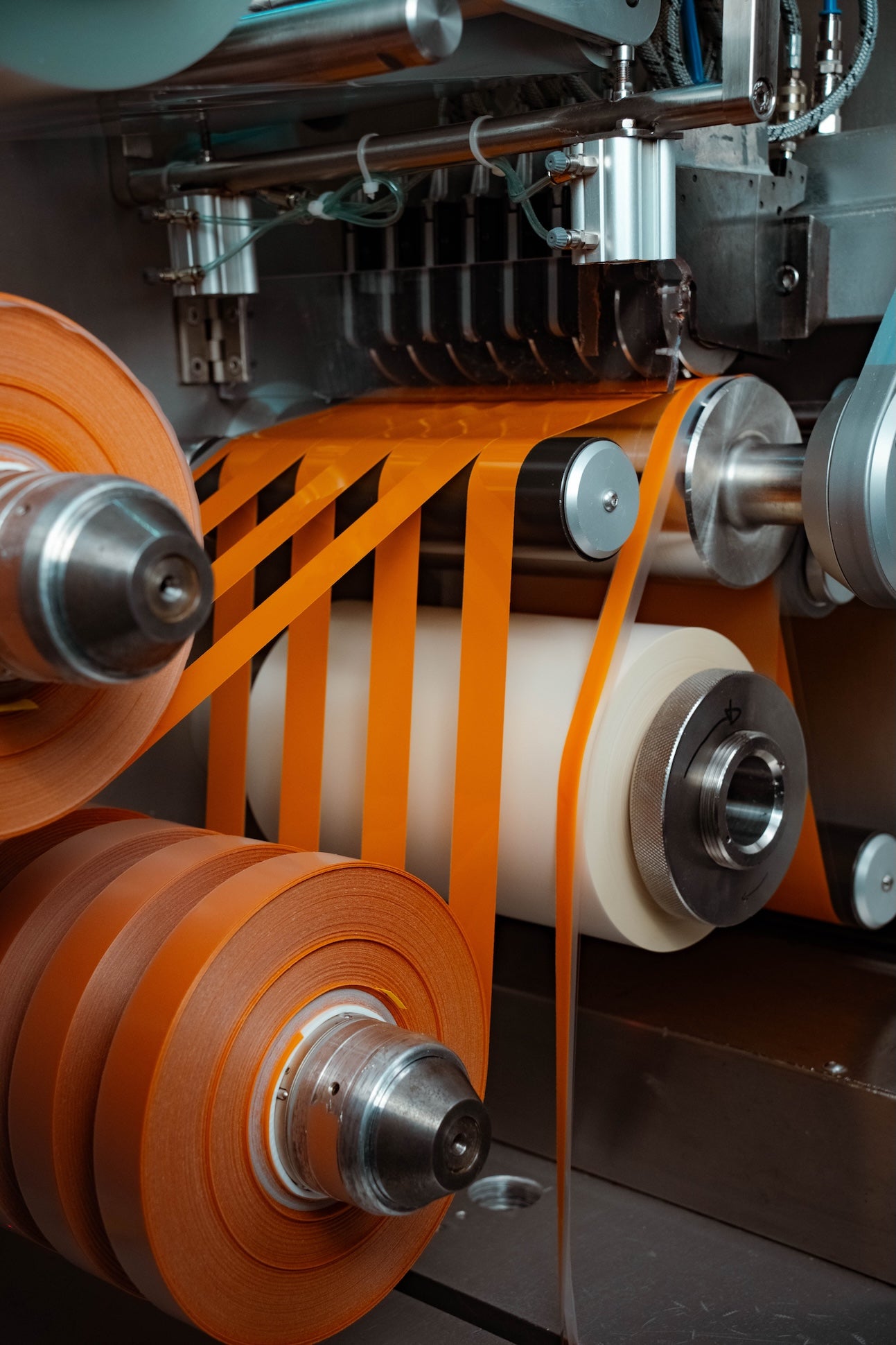

Step 3 - Slitting

The roll of dry mass is submitted to the slitting process, to cut the roll with a calibrated blade, in the reels with the first dimension of the final surface of the films.

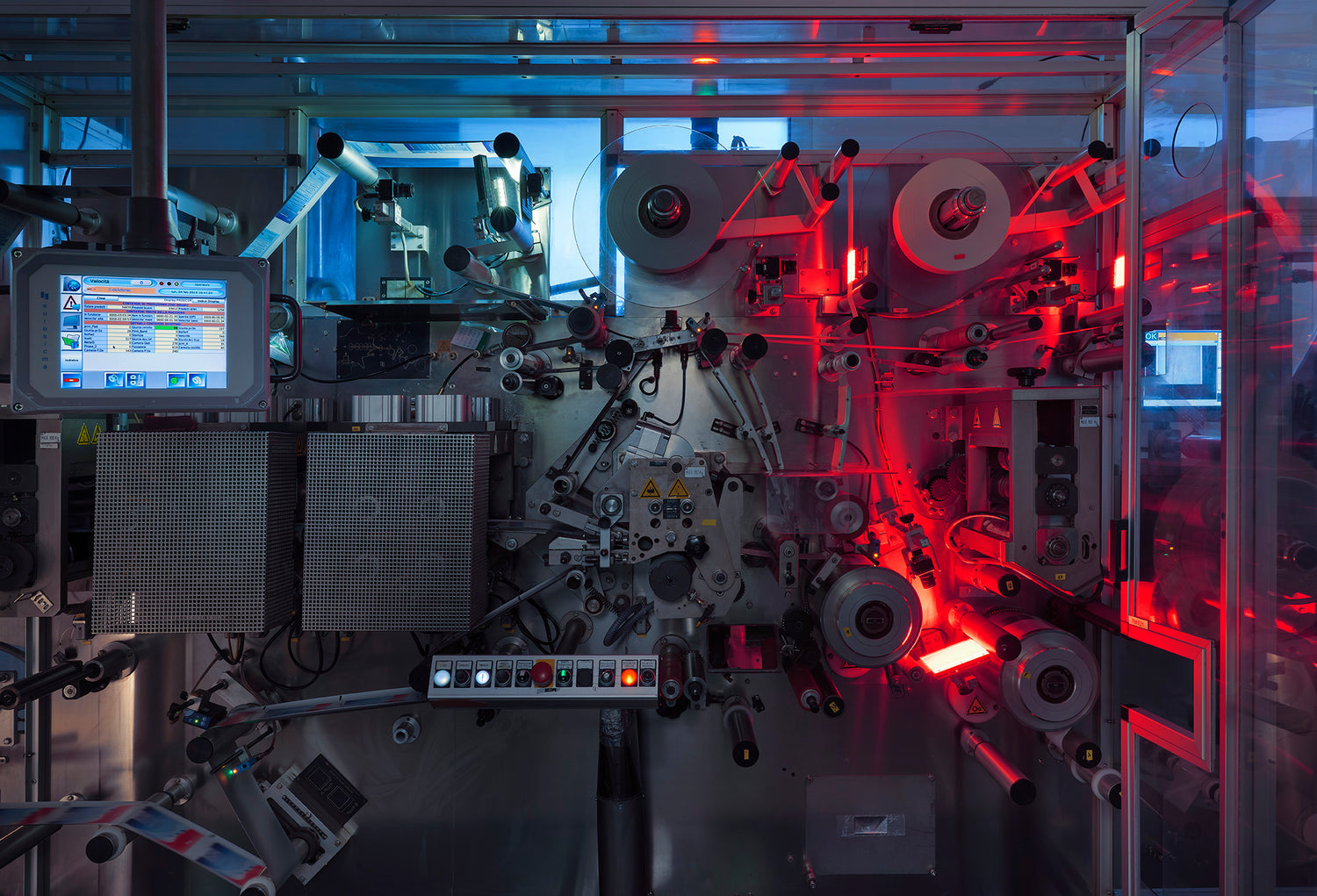

Step 4 - Film formation and packaging

Punched, pouched, sealed: The films are then individually packaged using a pouch forming machine. The sachet of compound material is fed inside and then a heat-sealing machine seals the pouch.

The final product

The ODFs obtained have a thickness of a few hundred microns. A correct coating process makes it possible to guarantee a uniform content in line with the pharmaceutical requirements, ensuring that the concentration of active ingredients is constant over the entire area of the film.